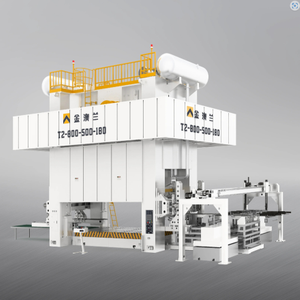

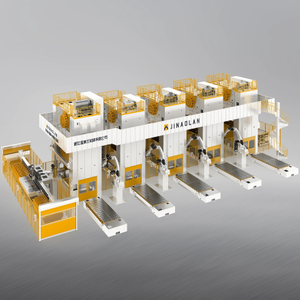

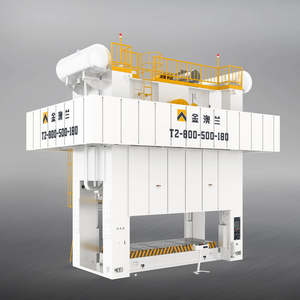

The T4 series press is a four-point mechanical eccentric press with 4 sets of guide post and guide bushes. Its working table can be made larger than T2 series. KINGLAN T4 series press machine adopts mature technology and structure, and the key parts are all world famous brands; the structure design is reasonable, the performance is stable and reliable; in working state, there is enough static and dynamic stiffness to ensure the system has good dynamic quality; The accuracy and response speed of the selected CNC drive system and actuators meet the design standards. It can meet the quality requirements of the process and product of the processed parts for a long time. Press has excellent sealing performance, no leakage, easy operation and maintenance, beautiful appearance and excellent after-sales service. Only after the whole machine is installed and commissioned to be qualified in our own plant, it will be disassembled and transported to the customer for installation.

Mechanical Eccentric Press Features:

1The body the press is made of welded steel plate split structure or steel plate welded one-piece structure. The top seat in the split structure, the middle platform, and the base are pre-tightened by four reinforcing rods to form a high rigidity.

2.The press uses eccentric gears for stable transmission and low noise.

3.Guided by a four-corner eight-sided guide rail, the lateral force is small and the precision is high.

4.The working table of the press can be selected as fixed or forward and backward moving, left and right moving and “T” type moving, etc. The user can select according to the specific conditions such as equipment arrangement, single machine or production line. It is convenient and quick to change the mold using moving trolley.

5.The model of the press can be air-cushion fixed stroke or adjustable stroke to meet the technical requirements of various complex and tensile parts in structure.

6.The lubrication system of the press adopts an automatic circulation system, continuous fixed-point and quantitative oil supply methods, and has fault detection devices such as blockage, crack and insufficient oil.

7.The electrical control system of the press adopts a programmable (PLC) control system, various functions such as the electronic cam, the control angle monitoring and display, and the pressure tonnage monitoring and display are controlled by PLC.