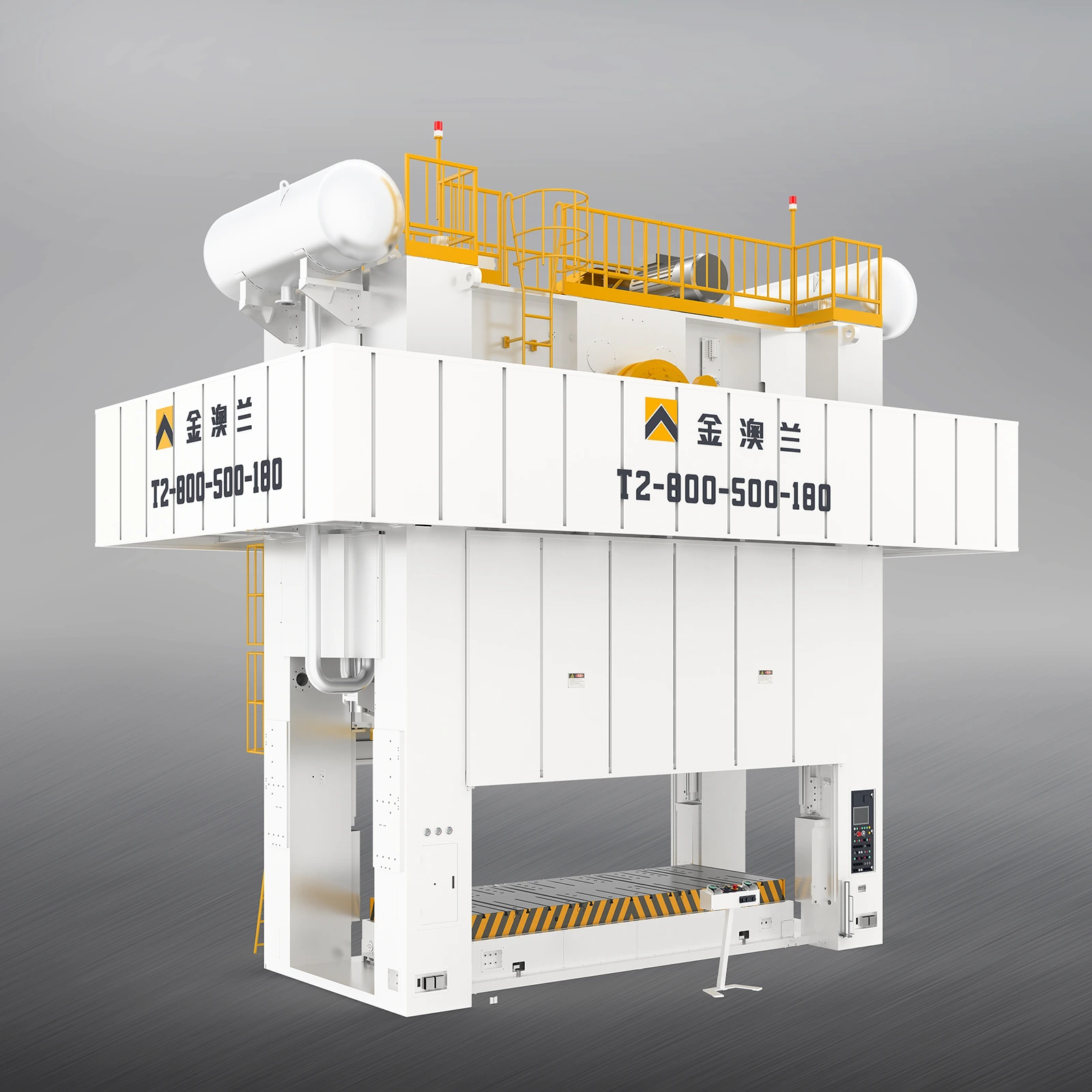

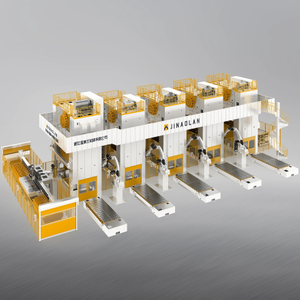

CHARACTERISTICS OF T2 SERIES EQUIPMENT

1、 Main part of press frame adopts welded steel plate in split structure or welded steel plate integral structure. The top crown, middle body and base seat in the split structure are

pre-tensioned by four reinforcing rods to form an integrated structure, high rigidity body.

2、Press adopts eccentric gear, which has stable transmission and low noise.

3、Long guide rail with four corners and eight sides has small lateral force and high precision.

4、The worktable of the press can be fixed type or movable, it can be front moving, backward moving, left and right moving or in a “T” shape moving. The user can choose bolster type according to different conditions such as equipment layout, single machine or production line. Certainly. The movable bolster makes it easy and fast to change molds.

5、Die cushion of the press can use air cushion fixed stroke or adjustable stroke to meet the process requirements of various parts in complex structures and deep drawing.

6、The lubrication system of the press adopts an automatic circulation system, continuous fixed-time and quantitative oil supply, and is equipped with fault detection devices such as pipeline blockage, rupture, and insufficient oil volume.

7、The electrical control system of the press adopts a programmable (PLC) control system, various functions such as visual electronic cam angle, braking angle monitoring and display, pressure monitoring and tonnage display are realized through PLC control.