Views: 0 Author: Site Editor Publish Time: 2026-02-12 Origin: Site

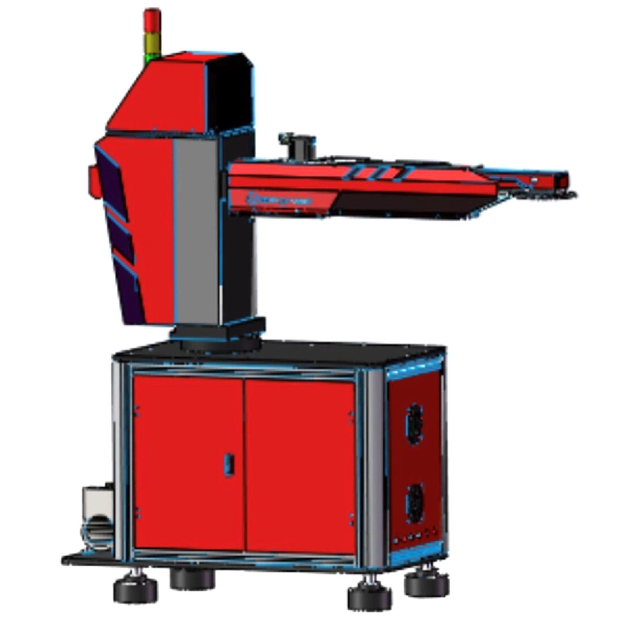

Choosing the right type of manipulator for your production line can significantly impact your manufacturing efficiency, cost-effectiveness, and overall system integration. With numerous options available, manufacturers must evaluate their needs carefully before making a decision. KINGLAN, a leading provider of automation solutions, offers both 2D manipulators and 3D manipulators, each designed to address specific challenges in automation. This article explores the differences between 2D vs 3D manipulators, providing an in-depth analysis to help you determine which is the best fit for your operation.

In the world of industrial automation, the success of your production line depends heavily on the tools and machinery you choose to integrate. With manufacturing processes evolving rapidly, automation has become a cornerstone of modern industries, offering unparalleled speed, accuracy, and cost savings. The 2D manipulator and 3D manipulator are two of the most commonly used automation tools, each designed for different applications based on their capabilities.

Understanding the differences between these two types of manipulators is crucial to ensuring that you select the right system for your needs. The wrong choice can lead to inefficiencies, higher costs, and complex system integration. This article aims to explain the differences between the 2D manipulator and the 3D manipulator, helping you make an informed decision to optimize your production line.

The 2D manipulator and 3D manipulator are robotic arms used in industrial automation to handle materials in production lines. However, the key difference lies in their movement capabilities.

A 2D manipulator is a robotic arm that moves along two axes: the X-axis (horizontal) and the Y-axis (vertical). This allows it to handle materials in a fixed, planar space, typically for simple tasks like loading, transferring, and unloading parts. The 2D manipulator is designed for operations where the material does not need to be moved in three-dimensional space, making it ideal for straightforward, repetitive tasks.

A 3D manipulator, on the other hand, operates across three axes: X, Y, and Z. The Z-axis adds vertical depth, allowing the manipulator to move materials not only horizontally and vertically but also in depth. This flexibility makes the 3D manipulator suitable for more complex tasks, such as assembling parts, welding, and handling materials that require multi-directional movement. With the ability to move in three-dimensional space, a 3D manipulator can tackle more dynamic and intricate tasks than its 2D counterpart.

While the 2D manipulator excels at high-speed, repetitive tasks in a planar environment, the 3D manipulator is ideal for operations requiring a more flexible approach.

Feature | 2D Manipulator | 3D Manipulator |

Axes of Movement | X–Y only | X–Y–Z & orientation |

Complexity | Lower | Higher |

System Cost | Lower | Higher |

Application Suitability | Simple planar transfers | Complex spatial tasks |

Integration Difficulty | Easy | Moderate |

As shown in the table, the 2D manipulator offers simpler motion along two axes, making it ideal for tasks where accuracy and speed are more important than flexibility. On the other hand, the 3D manipulator is a more complex system, providing versatile movement that is suitable for intricate operations requiring precise spatial positioning.

The 2D manipulator is well-suited for tasks that involve simple, repetitive material handling in a controlled space. In environments like metal stamping, where parts are processed quickly and with high precision, a 2D manipulator can excel. Here’s when you should consider using a 2D manipulator:

High-Speed Production: If your production line requires fast, high-volume handling of materials, a 2D manipulator can keep up with the speed, offering quick pick-and-place operations.

Cost-Sensitive Applications: When budget constraints are a priority, a 2D manipulator offers a more affordable solution compared to the more complex 3D alternatives.

Simple, Repetitive Tasks: For straightforward tasks like loading stock, part transfer, and unloading, a 2D manipulator is a cost-effective solution that does not require complex movement capabilities.

Shorter Integration Time: A 2D manipulator can be integrated more easily and quickly into your production line, reducing setup time and enabling faster deployment.

For manufacturers focused on improving efficiency and reducing operational costs, the 2D manipulator provides a high-performance yet simple solution.

While the 2D manipulator is great for simple tasks, there are instances where the flexibility and range of motion of a 3D manipulator are required. Here are the scenarios where a 3D manipulator is the better choice:

Complex Spatial Positioning: If your production process involves multi-dimensional movement or requires complex part assembly, a 3D manipulator can handle tasks that the 2D manipulator cannot.

Multi-Directional Handling: Tasks such as multi-axis welding, robotic assembly, or material handling that needs depth manipulation require the use of a 3D manipulator.

High Flexibility: In cases where the production line needs to handle parts in different orientations or in constrained spaces, a 3D manipulator offers the flexibility to work from different angles and depths, optimizing the production process.

Advanced Manufacturing Processes: Industries such as automotive assembly, aerospace manufacturing, and complex electronic assembly benefit from the advanced capabilities of a 3D manipulator to handle parts in intricate or unpredictable environments.

For tasks that demand versatility and precise spatial control, the 3D manipulator is the ideal solution.

The most significant technical difference between 2D and 3D manipulators lies in their movement capabilities. The 2D manipulator only moves along two axes—X and Y—limiting its function to horizontal and vertical movements. This simple design makes the 2D manipulator easy to integrate and use in high-speed environments where space and complexity are limited.

On the other hand, a 3D manipulator moves in three dimensions—X, Y, and Z—providing additional flexibility. The added Z-axis movement allows the 3D manipulator to pick up objects, rotate them, or handle them in three-dimensional space, which makes it ideal for more complex tasks. However, the complexity of its design means that it requires more advanced programming, integration, and maintenance, making it more expensive and difficult to implement.

The choice between a 2D manipulator and a 3D manipulator can significantly impact your production line’s efficiency, cost, and complexity. When choosing the right manipulator, manufacturers should consider factors like:

Investment Return: The upfront cost of a 2D manipulator is lower than a 3D manipulator, making it a more budget-friendly option for simple tasks. However, if your business requires more complex automation and flexibility, investing in a 3D manipulator may yield better long-term benefits.

Maintenance Costs: A 2D manipulator typically incurs lower maintenance costs, as it is simpler to operate and requires less sophisticated technology. In contrast, 3D manipulators often require more regular maintenance due to their complex movement and advanced systems.

Ease of Use and Integration: The 2D manipulator is easier to integrate into existing production lines and easier for operators to use, especially when only simple tasks need to be automated. 3D manipulators, while offering greater versatility, often come with a steeper learning curve for integration and operation.

Choosing between a 2D manipulator and a 3D manipulator should not be based on trends or buzzwords but on the specific requirements of your production line. The 2D manipulator is the ideal solution for simple, repetitive tasks that require speed and cost-effectiveness. In contrast, the 3D manipulator is better suited for applications requiring advanced movement capabilities, flexibility, and versatility.

At KINGLAN, we provide high-quality automation solutions that cater to both simple and complex manufacturing needs. By selecting the right manipulator for your operation, you can maximize efficiency, reduce costs, and enhance overall productivity.

Looking for a solution to optimize your production line? Contact KINGLAN today to learn more about our 2D and 3D manipulators and discover how they can help enhance your press automation processes.

Q1: What’s the main difference between a 2D and 3D manipulator?

A 2D manipulator moves along the X and Y axes, while a 3D manipulator can move along the X, Y, and Z axes, offering more flexibility in handling complex tasks.

Q2: When should I use a 2D manipulator?

A 2D manipulator is ideal for high-speed, repetitive tasks that only require horizontal and vertical movement.

Q3: What are the applications for a 3D manipulator?

A 3D manipulator is used for complex tasks that require multi-directional handling and precise spatial positioning, such as assembly or welding.

Q4: How do I decide which manipulator is right for my production line?

Consider factors such as complexity, budget, speed, and the type of tasks that need to be automated. 2D manipulators are cost-effective for simpler tasks, while 3D manipulators offer more flexibility for advanced applications.