CHARACTERISTICS OF T2 MULTI STATION SERIES EQUIPMENT

1、 Main part of press frame adopts welded steel plate in split structure or welded steel plate integral structure. The top crown, middle body and base seat in the split structure are pre-tensioned by four reinforcing rods to form an integrated structure, high rigidity body.

2、Press adopts eccentric gear, which has stable transmission and low noise.

3、Long guide rail with four corners and eight sides has small lateral force and high precision.

4、The worktable of the press can be fixed type or movable, it can be front moving, backward moving, left and right moving or in a “T” shape moving. The user can choose bolster type according to different conditions such as equipment layout, single machine or production line. Certainly. The movable bolster makes it easy and fast to change molds.

5、Die cushion of the press can use air cushion fixed stroke or adjustable stroke to meet the process requirements of various parts in complex structures and deep drawing.

6、The lubrication system of the press adopts an automatic circulation system, continuous fixed-time and quantitative oil supply, and is equipped with fault detection devices such as pipeline blockage, rupture, and insufficient oil volume.

7、The electrical control system of the press adopts a programmable (PLC) control system, various functions such as visual electronic cam angle, braking angle monitoring and display, pressure monitoring and tonnage display are realized through PLC control.

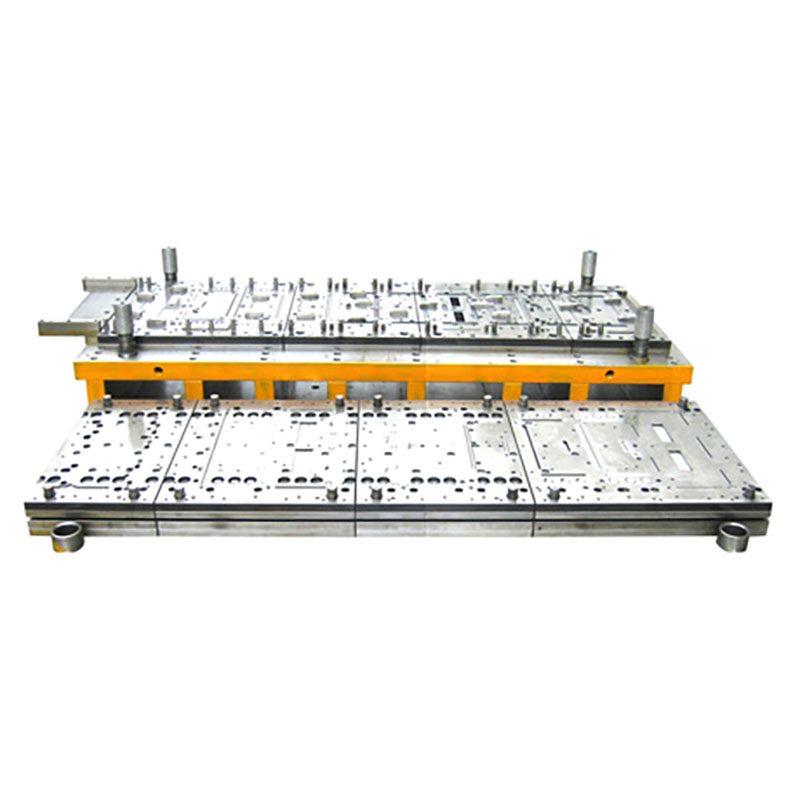

Progressive Die Set Overview

Sheet metal progressive die can complete punching, bending, stretching, forming and other processes until one part is completed.

If the complexity of the stamping is high, the progressive die can sometimes only complete the previous processing in the work piece stamping. The subsequent stamping processing is completed by the stage die.

In the progressive die, before the completion of all processes, the piece and the strip are not separated, the spacing between the adjacent two work steps must be the same, otherwise the material cannot be fed.

Progressive Die Stamping Features

Advantages

1. Progressive die is a multi-task sequential die. It can include punching, bending, deep drawing, forming and many other processes, so it has higher production efficiency than compound die, and can produce quite complex stamping parts.

2. Progressive die operation is safe because manpower does not have to enter the hazardous area.

3. In the progressive die design, process can be dispersed. Because the process does not have to be concentrated in the same station, there is no problem of “minimum wall thickness” in the compound mold. Therefore, the mold is relatively strong and has a long service life.

4. The progressive die is easy to realize automation, including automatic feeding, automatic output (material), automatic riveting.

5. The waste of the progressive die will drop downwards, and the work piece will come out downward or exit from the side of the mold. Therefore, high-speed presses can be used for its stamping, such as terminal dies, high-speed dies etc.

6. In general, one set of progressive die uses one press machine, so the use of progressive die can reduce the press quantity, workshop area, semi-manufactured goods transportation and storage area, and manpower required for stamping.

Disadvantages

The disadvantage of the progressive die is that the structure is complicated, the manufacturing precision is required to be high, the manufacturing cycle is long, and the cost is high.

In addition, for a relatively large and complex work piece, if a progressive die is used, the die is often large size, and sometimes it cannot be matched with the press machine.

Because the progressive die punches out the shape of the work piece in different steps at a time, there is a positioning error for each stamping. Therefore, if there is a part with a relatively high position accuracy on the work piece, try to punch out at the same station in the mold to ensure its accuracy.

Material Utilization

Because the use of progressive die requires a tie-up or side strip, the material utilization rate is lower than the blanking die; so precious metals should not use progressive die; Considering the shape of the product, using appropriate layout methods (some layout methods may make the mold more complex) can also increase the material utilization of the product.

Stamping Material

Materials used for progressive die are generally long strips. If the material is thicker or the production batch is small, the sheet can be used; if the material is thin and the batch is large, consider using the coil. When coil is used, the material can be automatically fed, and the high-speed press can be used for automatic stamping.

Progressive die has strict requirements on the width of the material: when it is too wide, the material cannot enter the guide plate and the feeding is not smooth; if it is too narrow, it affects the feeding accuracy, and it is also easy to damage the mold.

Feeding Method

1. Feed manually. Applicable to the case that the production batch is not large, the material is thick, and the work piece is large (for example, 3.0mm stainless steel work piece). This type of feeding method is not as efficient as automatic feeding.

2. Automatic feeder feeding. It is generally suitable for the feeding of coils in stamping. It is characterized by high feeding accuracy and high production efficiency, which is often used in mass production.

3. Attach a self-made feeding device to the mold, such as small sliders, ratchets and other structures, but generally less used this way.