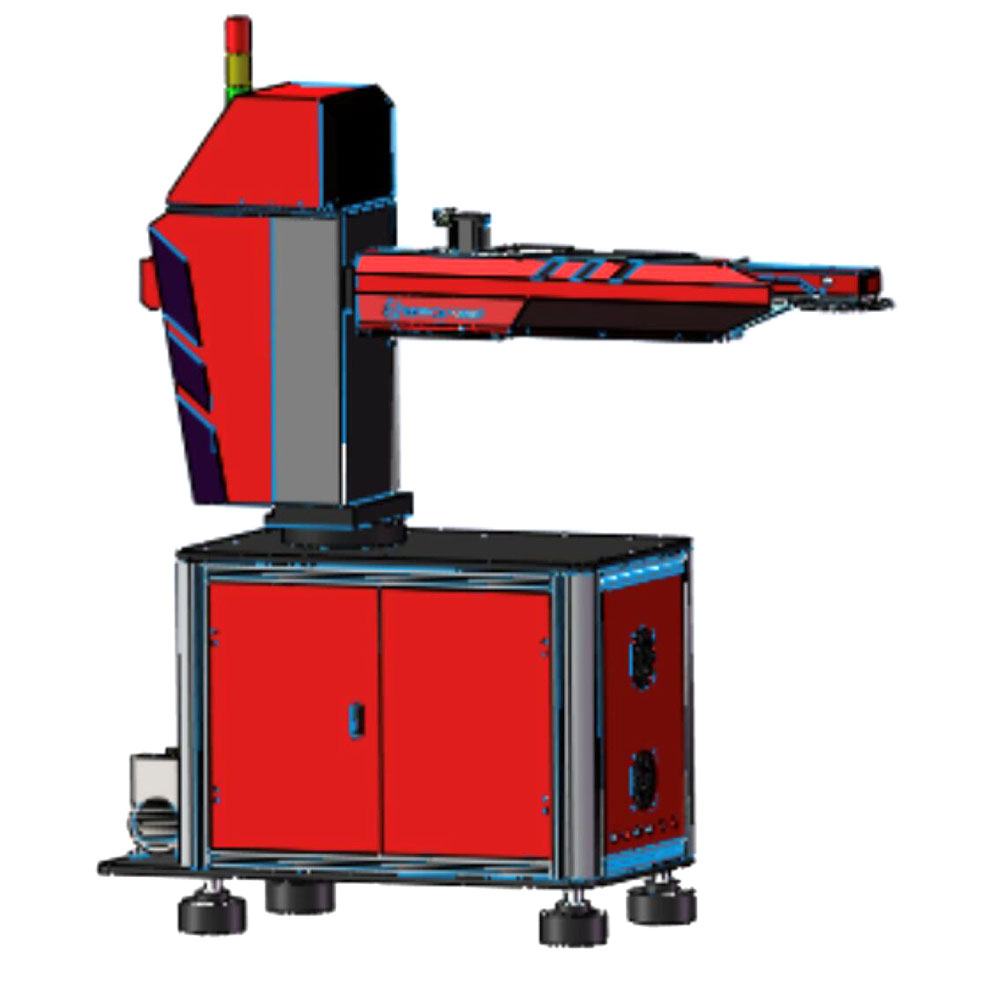

Independent Roboter Manipulator Features

1.The use of dual servo drive, dual retractable arm suspension, and the main Bar, X-axis, Z-axis can achieve synchronous movement, move the workpiece from one station to the next station, to improve the degree of automation;

2. The suction arm aluminum profile has a strip groove, and the arm can be adjusted according to the size of the workpiece.

3. The material can be grabbed (single or combined) by vacuum chucks, electromagnets, vacuum jaws, etc.

4. The end is equipped with safety racks, sound, and light alarm devices and other related safety measures;

5. Each robot arm is equipped with a sensor detection device (proximity sensor, vacuum detection)

6. The line body has dropping frame function, which is more suitable for the special process requirements in the stamping;

7. The line body can connect with roll feeders, sheet material stackers, and tapping machines, turning machines, riveters, and other auxiliary equipment to achieve continuous production.

Technical Parameters (machine can be customized)

| Model | Independent manipulatorseries |

| Drive mode | Full-servo |

| Operation mode | Central operating platform (touch screen) |

| X-axis stroke (left-right forwarding) | 4000 (customizable) |

| Z-axis stroke (lifting) | 150mm (customizable) |

| Feeding precision | ±0.20mm |

| Max. gripping weight | 15kg |

| Gripping detection | Proximity sensor and vacuum detection |

| Gripping mode | Vacuum-absorption, electromagnet, and gripping jaw |

| External power requirement | 3P AC380V |

| Operation rhythm |