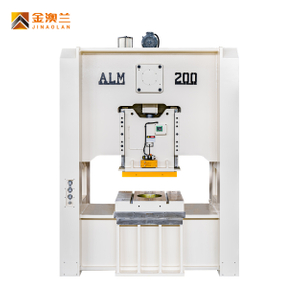

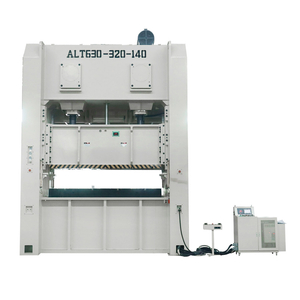

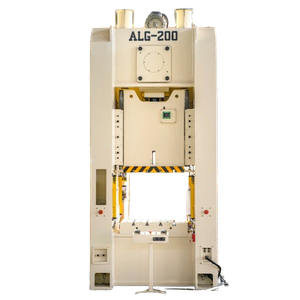

H Type Press Machine Features:

1. The slider guide adopts a four-corner and eight-faced super long guide rail which has a strong anti-offset ability. The push-pull bolts on the column facilitate the adjustment of the guide rail clearance to ensure the accuracy of the retention.

2. With electronic cam, it has the function of preventing the slider from repeating in the single stroke operation.

3. The oil tank of the hydraulic system has oil level monitoring, cleanliness detection and alarm function. The oil pump inlet is equipped with an oil filter, and the oil outlet is equipped with pressure detection to ensure that the hydraulic system oil meets the design standards.

4. The control core of the press adopts PLC and is equipped with a touch screen man-machine interface. The components of the press system are reasonably configured, and the key components are imported well-known brands.

5. It adopts international famous brand photoelectric protection device to make sure press in completely safe working conditions.

6. Each of the four columns has an emergency stop button. Press is equipped with a mobile button station and with an emergency stop button.