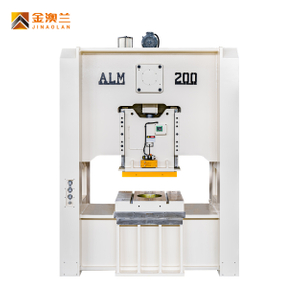

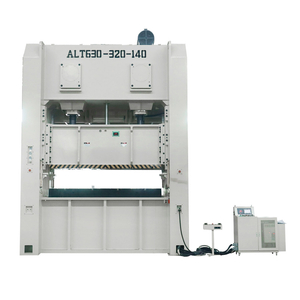

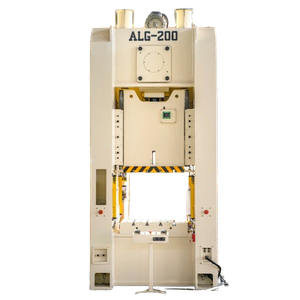

The battery shell deep drawing metal stamping press machine and the battery shell pres line conform to the high-speed development needs of new energy vehicles and smart phone batteries. With the concept of “innovation”, the automatic multi-station stamping press has been designed and developed by KINGLAN, which has been successfully applied to the battery shell production field.

The battery case special multi-station press can carry out the process combination of blanking, stretching, trimming, explosion-proof printing, deburring etc., with manual, inching, single operation, variable frequency continuous operation and emergency stop function; battery Shell special multi-station press line configuration: material automatic decoiler machine, pneumatic automatic feeder, fixed table multi-station press, transmission system, cam returning system, multi-station flexible manipulator, material ejection system, multi-station progressive die, mold lubrication system, mold cooling system, horizontal trimming die mechanism, automatic mold inspection system, product conveyor, etc.