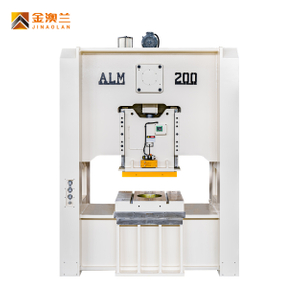

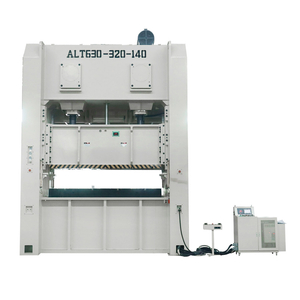

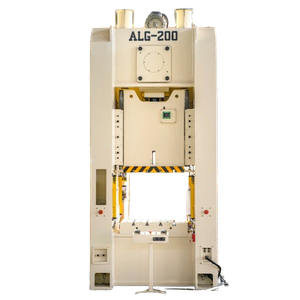

The ALF series h type power press machine has an integrated welding machine body and a crankshaft drive. Closed single-point circulation thin oil lubrication, which further improves the working environment of the machine tool; super long eight-sided guide rail, excellent precision retention ability. The straight-column, one-piece body has better rigidity than C-type press machine. The perfect man-machine protection is in line with press safety standards.

Mechanical Punch Press Machine Features:

1. Increased productivity and production flexibility;

2. Ensure high precision stamping products;

3. Cutting material with low noise, low vibration and easy operation

4. The deformation of the frame is small, die life is greatly improved, and the reliability is strong.

5. Built-in eight-sided long guide rail, high rigidity body

6. PLC control system, convenient punching automation connection

7. Press is with high rigidity, suitable for big thickness products production.