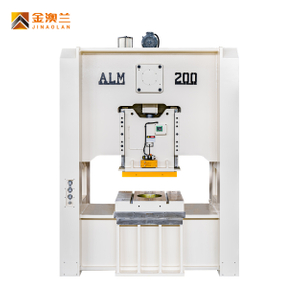

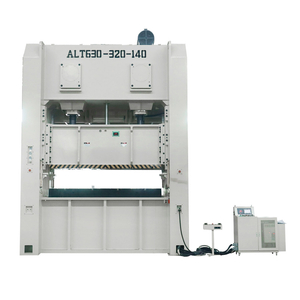

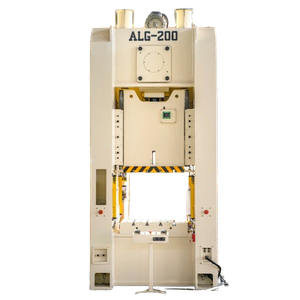

ALE series h frame power press machine is one of the hot products of KINGLAN high-precision press machines. It adopts the structure of closed type double-crank, frame made by welded steel plate which processed through heat treatment and elimination of internal stress. The transmission center and the center of whole machine tend to be the same to ensure accurate and stable stamping.

The clutch/brake device of the high-precision steel frame press is highly sensitive, the slider adjusting mechanism is adjusted to high precision, and the production is to be safer and faster. The crankshaft, gear, gear shaft and other friction parts of closed double-crank precision press are hardened and heat-treated and then ground. It has high wear resistance and balance, stable performance, ensuring the quality and service life of CNC press machine. The high performance power press punching machine can be equipped with an automatic feeder and engaged in automatic transfer of the entire production line.