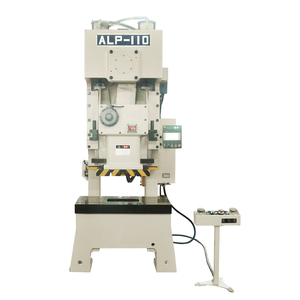

The ALP series of open-type fixed table presses are general-purpose presses for sheet metal stamping. They are suitable for various cold stamping processes such as shearing, punching, blanking, bending and shallow drawing. It is manufactured in strict accordance with Japanese JIS Class 1 accuracy standards and is superior to domestic standards.

The main components of our c frame punch press are all processed by imported CNC equipments. Japanese high-quality bearings and imported oil seal linings ensure the accuracy and longevity of the machine.